What is metal stamping Idea

Home » Trend » What is metal stamping IdeaYour What is metal stamping images are ready. What is metal stamping are a topic that is being searched for and liked by netizens now. You can Download the What is metal stamping files here. Find and Download all royalty-free photos and vectors.

If you’re looking for what is metal stamping images information connected with to the what is metal stamping keyword, you have pay a visit to the right blog. Our site frequently provides you with hints for seeking the highest quality video and image content, please kindly surf and find more enlightening video articles and graphics that fit your interests.

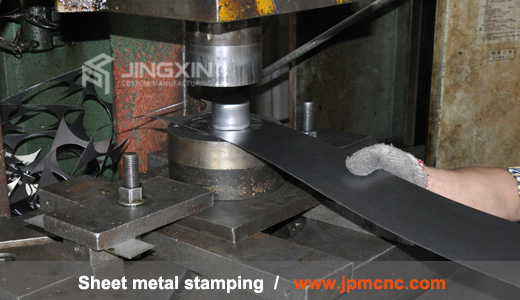

What Is Metal Stamping. Some the materials that are run through the custom precision metal stamping process include copper, bronze, stainless steel & copper and cold rolled steel. That offer metal stamping services to deliver components for. Metal stamping is an integral part of electronics manufacturing process. Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes.

metalstamping Jayco Manufacturing From jaycomfg.com

metalstamping Jayco Manufacturing From jaycomfg.com

Punched material is normally in sheets but rolled metals can be used as well. Metal stamping is an integral part of electronics manufacturing process. In house tooling design and fabrication, tooling. This is done in order to create complex designs for various industries, such as consumer goods, aviation, electronics, telecommunications, automotive manufacturing, food and beverage, and many more. With almost as many styles as industries that the process serves, recognizing and understanding the complexities of this part formation method becomes a critical aspect of selecting services for part creation. Metal stamping, metal fabrication, and mechanical.

Handling various types of material and finishing.

Waukesha metal products is an innovative leader in precision sheet metal stamping and fabrication, component assembly, and tool and die manufacturing. Punched material is normally in sheets but rolled metals can be used as well. Custom metal stamping with any metal material. It involves a number of processes to form the metal into the desired shape. There are thousands of companies across the u.s. A variety of metal stamping options.

Source:

Source:

It involves a number of processes to form the metal into the desired shape. Waukesha metal products is an innovative leader in precision sheet metal stamping and fabrication, component assembly, and tool and die manufacturing. Metal stamping is the manufacturing process of converting metal sheets into different shapes with the help of dies and stamping presses. It’s very rare that an entire metal. Custom metal stamping with any metal material.

Source:

Source:

Precision metal stamping we produce precision metal stamping from materials as thin as.003” and are capable of offering finished stamped metal parts to you with tolerances as tight as ±.0005”. It can even pierce, or restrike a metal blank. It is a complex process that can include a number of metal forming techniques — blanking, punching, bending and piercing, to name a few. Punched material is normally in sheets but rolled metals can be used as well. Metal stamping, metal fabrication, and mechanical.

Source: jpmcnc.com

Source: jpmcnc.com

There are thousands of companies across the u.s. Metal stamping, metal fabrication, and mechanical. This is done in order to create complex designs for various industries, such as consumer goods, aviation, electronics, telecommunications, automotive manufacturing, food and beverage, and many more. Metal stamping involves the use of a wide array of processes and techniques such as punching, blanking, embossing, coining, bending, and flanging. Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes.

Source: fairlawntool.com

Source: fairlawntool.com

And offers complete metal stamping, metal fabrication, and mechanical assembly products & services to their customers! And offers complete metal stamping, metal fabrication, and mechanical assembly products & services to their customers! With almost as many styles as industries that the process serves, recognizing and understanding the complexities of this part formation method becomes a critical aspect of selecting services for part creation. Assembly are at the core of our expertise. Metal stamping, metal fabrication, and mechanical.

Source:

Source:

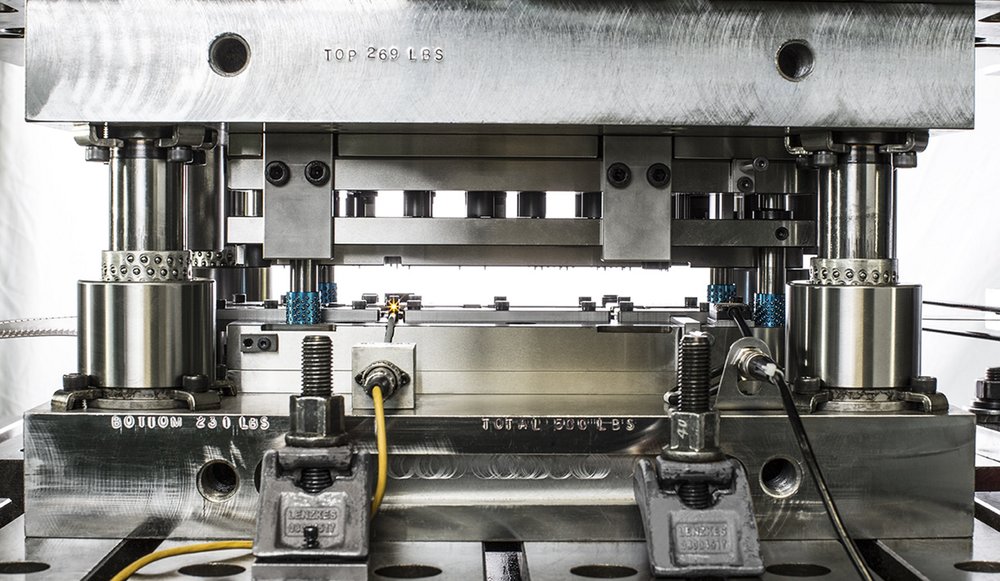

Depending on the product design, your metal stamping manufacturer will likely have stock dies and tools available for standard shaping, punching, coining, bending, and embossing; A variety of metal stamping options. Metal stamping transforms sheet metal into usable parts and tools for numerous industries. With almost as many styles as industries that the process serves, recognizing and understanding the complexities of this part formation method becomes a critical aspect of selecting services for part creation. The company’s metal stamping operations consist of a variety of presses primarily comprised of bruderer presses for the highest quality stamping action.

Source: meticulousblog.org

Source: meticulousblog.org

It is a complex process that can include a number of metal forming techniques — blanking, punching, bending and piercing, to name a few. The sheet metal can come in either blank or coil form, and common stamping operations include blanking, punching, coining, drawing, embossing, piercing. It is a complex process that can include a number of metal forming techniques — blanking, punching, bending and piercing, to name a few. Metal stamping is an integral part of electronics manufacturing process. Facility has grown to 30,000 sq.

Source: atfctooling.com

Source: atfctooling.com

Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes. It’s very rare that an entire metal. Handling various types of material and finishing. Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes. From silver stamps and more within our impressart metal stamps collection, shop the whole range online.

Source: fairlawntool.com

Source: fairlawntool.com

Metal stamping involves the use of a wide array of processes and techniques such as punching, blanking, embossing, coining, bending, and flanging. Metal stamping transforms sheet metal into usable parts and tools for numerous industries. With almost as many styles as industries that the process serves, recognizing and understanding the complexities of this part formation method becomes a critical aspect of selecting services for part creation. Depending on the product design, your metal stamping manufacturer will likely have stock dies and tools available for standard shaping, punching, coining, bending, and embossing; The sheet metal can come in either blank or coil form, and common stamping operations include blanking, punching, coining, drawing, embossing, piercing.

Source:

Source:

From metal hand stamps to fully automated machines, a wide range. Metal punching is a fabricating process that removes a scrap slug from the workpiece when the punch enters the punching die. That offer metal stamping services to deliver components for. And offers complete metal stamping, metal fabrication, and mechanical assembly products & services to their customers! Depending on the product design, your metal stamping manufacturer will likely have stock dies and tools available for standard shaping, punching, coining, bending, and embossing;

Source: waykenrm.com

Source: waykenrm.com

It involves a number of processes to form the metal into the desired shape. From metal hand stamps to fully automated machines, a wide range. A variety of metal stamping options. It can even pierce, or restrike a metal blank. But our point of interest is the seemingly small but otherwise significant dot peen marking segment of the industry.

Source: noobpreneur.com

Source: noobpreneur.com

From silver stamps and more within our impressart metal stamps collection, shop the whole range online. Metal stamping requires finely calibrated and specialized equipment, but the process is relatively simple. Assembly are at the core of our expertise. Precision metal stamping we produce precision metal stamping from materials as thin as.003” and are capable of offering finished stamped metal parts to you with tolerances as tight as ±.0005”. Metal stamping is the manufacturing process of converting metal sheets into different shapes with the help of dies and stamping presses.

Source:

Source:

Metal stamping, metal fabrication, and mechanical. Punched material is normally in sheets but rolled metals can be used as well. Progressive die stamping is a metal forming process in which a metal strip is converted into components during several staged operations. You also come first when considering. That offer metal stamping services to deliver components for.

Source:

Source:

Metal punching is a fabricating process that removes a scrap slug from the workpiece when the punch enters the punching die. Metal stamping is an integral part of electronics manufacturing process. And offers complete metal stamping, metal fabrication, and mechanical assembly products & services to their customers! Assembly are at the core of our expertise. Progressive die stamping is a metal forming process in which a metal strip is converted into components during several staged operations.

Source: theinscribermag.com

Source: theinscribermag.com

Metal stamping requires finely calibrated and specialized equipment, but the process is relatively simple. Handling various types of material and finishing. Generally, a metal stamping machine is available for forming, trimming, embossing, or flanging blank metal surfaces. You also come first when considering. From metal hand stamps to fully automated machines, a wide range.

Source:

Source:

A variety of metal stamping options. Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Metal punching is a fabricating process that removes a scrap slug from the workpiece when the punch enters the punching die. In metal stamping processes, the types differ from one another, depending on what shape they achieve. A variety of metal stamping options.

Source: dubay.me

Source: dubay.me

Rickotek metal products limited is a prefessional metal stamping manufactuer and rapid prototyping service provider, we not only provide a wide range of metal stamping services including deep drawn stamping, progresive die stamping, precision metal stamping and compound die stamping, but offer cnc machining services. Beginning as a tool and die manufacturer in 1975, apt’s. Some the materials that are run through the custom precision metal stamping process include copper, bronze, stainless steel & copper and cold rolled steel. Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Our manufacturing process includes the following techniques based on your specifications:

Source: floridaindependent.com

Source: floridaindependent.com

The company was established in 2002, is a subsidiary of ht presswork sdn bhd malaysia, and specializing in manufacturing of precision metal stamping, and aluminium parts that are used in consumer electronics such as car and home audio, appliance. Generally, a metal stamping machine is available for forming, trimming, embossing, or flanging blank metal surfaces. But our point of interest is the seemingly small but otherwise significant dot peen marking segment of the industry. Metal stamping is the manufacturing process of converting metal sheets into different shapes with the help of dies and stamping presses. Beginning as a tool and die manufacturer in 1975, apt’s.

Source: goldenagebeads.com

Source: goldenagebeads.com

Precision metal stamping we produce precision metal stamping from materials as thin as.003” and are capable of offering finished stamped metal parts to you with tolerances as tight as ±.0005”. Pieces of flat sheet metal, typically referred to as blanks, is fed into a sheet metal stamping press that uses a tool and die surface to form the metal into a new shape. In house tooling design and fabrication, tooling. Multiple stations are set up along the production line, and each section performs different manufacturing tasks on the part as it is transported past. This is done in order to create complex designs for various industries, such as consumer goods, aviation, electronics, telecommunications, automotive manufacturing, food and beverage, and many more.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site value, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title what is metal stamping by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.

Category

Related By Category

- Polonez parcel service opinie Idea

- New directions treatment services v city of reading Idea

- Wayfair customer service opening times Idea

- Blue earth county human services address Idea

- Mount valley foundation services charleston Idea

- Gale contractor services tempe az information

- Managed network services pricing information

- United healthcare shared services geha information

- Washoe legal services reno nv 89501 Idea

- Lute riley honda service coupons information